Fire protection knowledge of cable laying

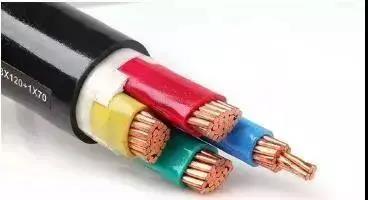

1. Choose flame-retardant wires and cables

Fireproof mechanism of flame-retardant wires and cables:Under the heat of the combustion reaction, the flame retardant in the condensed phase thermally decomposes and absorbs heat, which slows down the temperature rise in the condensed phase and delays the thermal decomposition rate of the material. At the same time, it releases a chain reaction free radical blocker to make The branch interruption of flame and chain reaction slows down the gas phase reaction speed, prevents the temperature rise in the condensed phase, and achieves the fire prevention effect;

Classification and selection of flame-retardant wires and cables:Flame-retardant cables mainly include ordinary flame-retardant wires and cables, halogen-free low-smoke flame-retardant cables, low-halogen low-smoke flame-retardant cables, and fire-resistant cables. These products have different manufacturing technologies, performance characteristics, and application ranges.

2. Scientific design and installation

Blocking:Fire blocking is to use fire blocking materials to block the gaps where the cables pass through to prevent the cables from catching fire and prolonging combustion. The connection between the cable trench and the electrical panel, box, cabinet, partition wall, floor slab, etc. must be flame-retardant plugging. The cable fire door should be closed for a long time, and the gap between the cable fire board and the cable trench cover should be closed.Use soft plugging material to seal tightly at densely laid cables

Separate:The fire partition wall can divide the long cable tunnel and the cable channel into small sections to narrow the fire area. Fire-resistant partitions, aluminum silicate fiber felt, fire-resistant blocking materials, fire-resistant coatings, etc. can be used. The fire partition wall is made of slag wool, and it is used in the tunnel with the fire door;

Coating:Applying fire-resistant paint can prevent the cable from burning after fire. The fire-resistant and flame-retardant tape is easy to construct, not easy to fall off, has strong adaptability, and is cheap.In the part of the cable entering the cabinet to the terminal head, paint all cables with fire-retardant paint or wrap fire-retardant tape twice in the area of 2 to 3 meters on both sides of the fire-proof partition wall.

3. Set up fire prevention facilities

Set up the fire alarm system: According to the actual situation, select the appropriate alarm probe and the alarm system suitable for the characteristics of the cable layer. At present, the linear (or cable-type) temperature-sensing detector is widely used in cable trenches and pipeline wells. ;

High-pressure water spray fire extinguishing: High-pressure water spray fire extinguishing methods should be adopted in cable corridors and densely cabled areas. In order to make water spray fire extinguishing work in a timely and effective manner, a high-sensitivity monitoring and control system is required;

Strengthen the ventilation of the cable layer (well): Using natural ventilation conditions, set up vents on the cable layer as close to the outer wall as possible. At the same time, a mechanical smoke exhaust system with uninterrupted power supply should be established to pass automatic The alarm linkage turns on the exhaust fan.

4. standardize daily management

Maintain a good operating condition: to prevent defects, aging, moisture, damage, etc. due to the internal insulation of the cableThe cable's own fault causes the cable to be short-circuited, and the arc is fired. The cable with poor insulation is found in time, and it is taken out of operation;

Maintain a good operating environment: It is strictly forbidden for waste gas and waste water from the thermal system to flow into the cable trench and cable tunnel;

Strengthen the monitoring and management of cable heads: Cable heads are the weak link of the cable insulation due to many factors, and the power cable terminal heads and middle parts placed in the cable trenches, cable tunnels, cable trough boxes, and cable interlayers The joints must be registered and supervised to prevent the cable hair from catching fire during operation.

Note: This article is reprinted as a network resource. If you have any copyright infringement, please contact the administrator to delete it!

Company Profiles

Company Profiles Company Culture

Company Culture Message

Message Honor

Honor Video Center

Video Center Company Reality

Company Reality Pearl River Cable

Pearl River Cable Low Voltage Cable

Low Voltage Cable Medium Voltage

Medium Voltage Mineral Cable

Mineral Cable Control Signal Cable

Control Signal Cable Corporate News

Corporate News Cable Information

Cable Information Media Reports

Media Reports Network Reprint

Network Reprint