Three important indicators of wire and cable quality testing

The selection of qualified wire and cable products is related to the safety of people's production and life. For ordinary consumers, in addition to mastering how to select qualified wire and cable products, it is also necessary to understand the knowledge of routine monitoring of wires and cables. In the wire and cable quality inspection, there are mainly the following important indicators.

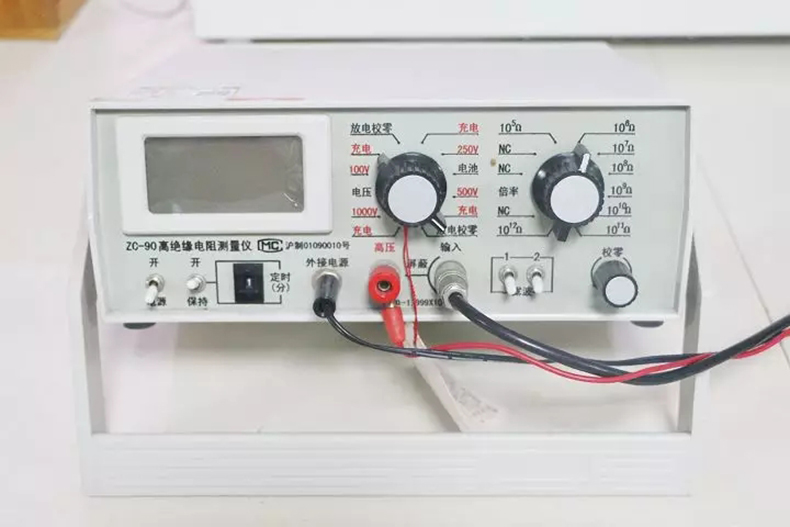

Insulation resistance test:

Insulation resistance is an important indicator reflecting the insulation characteristics of wire and cable products. It is closely related to the product's electrical strength, dielectric loss, and the gradual deterioration of insulating materials under working conditions. For communication cables, low insulation resistance between wires will also increase loop attenuation, crosstalk between loops, and long-distance power supply leakage on conductive cores. Therefore, insulation resistance is required to be higher than the specified value.

Defects in the process can be found by measuring the insulation resistance, such as the insulation is dry and impermeable or the sheath is damaged and damp; the insulation is polluted and conductive impurities are mixed in; the insulation layer is cracked due to various reasons. In the operation of wires and cables, the insulation resistance and leakage current are often tested as the main basis for continued safe operation.

At present, the measurement of the insulation resistance of wires and cables, in addition to the ohmmeter (shake meter), commonly used galvanometer comparison method (high resistance meter method-current method).

Measurement of capacitance and dissipation factor:

When the AC voltage is applied to the cable, current will flow. When the voltage amplitude and frequency are constant, the capacitance current is proportional to the capacitance (Cx) of the cable. For ultra-high voltage cables, the current of this capacitor may reach a value comparable to the rated current, which becomes an important factor limiting the cable capacity and transmission distance. Therefore, the capacitance of the cable is also one of the main electrical performance parameters of the cable.

In an AC electric field, the insulator in the cable will form dielectric loss due to leakage current and various polarizations. It is expressed in terms of dielectric loss factor or loss tangent (TAN). It not only wastes electrical energy, but also makes the dielectric (insulator) ) Heating, accelerating insulation aging, so TAN is also one of the main parameters of the cable.

Through the measurement of capacitance and dissipation factor, various insulation degradation phenomena such as insulation dampness, insulation layer and shielding layer falling off can be found. Therefore, capacitance and TAN are measured whether in cable manufacturing or cable operation. For high-voltage cables, Cx and TAN measurements are performed under their working conditions, that is, under power frequency and high voltage. High-voltage Xilin bridges are usually used. In recent years, current ratio transformer bridges have also been used.

Partial discharge measurement:

For oil-filled cables, there is basically no local power generation; even if the oil-paper cables have partial discharges, they are usually very weak, such as several PCs. Therefore, these cables may not be tested for partial discharges in the factory test. For extruded cables, not only the possibility of partial discharge is high, but the damage to plastic and rubber by partial discharge is also serious. With the increase of voltage level and the increase of working field strength, this problem becomes more serious. Extruded cables must be measured for partial discharge in the factory test.

There are many methods for measuring partial discharge. The discharge pulse can be measured based on the instantaneous charge exchange generated by the discharge (electrical measurement method); the voltage can also be measured based on the ultrasonic wave generated during the discharge (acoustic measurement); and it can also be measured based on the light generated by the discharge. , Measure the intensity of light (photometry). Basically, electrical measurement methods are used for cables.

Company Profiles

Company Profiles Company Culture

Company Culture Message

Message Honor

Honor Video Center

Video Center Company Reality

Company Reality Pearl River Cable

Pearl River Cable Low Voltage Cable

Low Voltage Cable Medium Voltage

Medium Voltage Mineral Cable

Mineral Cable Control Signal Cable

Control Signal Cable Corporate News

Corporate News Cable Information

Cable Information Media Reports

Media Reports Network Reprint

Network Reprint